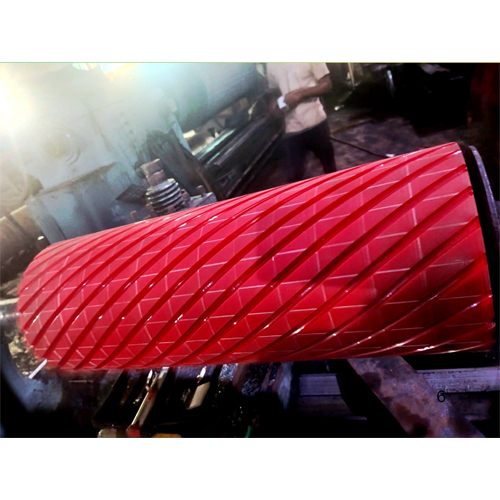

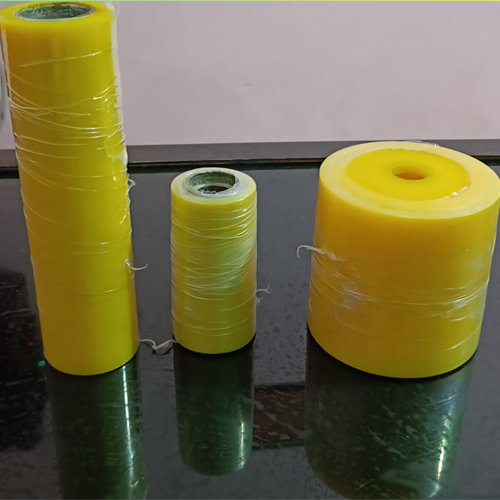

Tin Printing Roller with PU Coating

Price 30000.0 INR/ Piece

Tin Printing Roller with PU Coating Specification

- Coating

- Polyurathane Coating

- Weight

- 70 Kilograms (kg)

- Size

- 900

- Usage

- Tin Printing

- Material

- Polyurethane

- Height

- 150 Millimeter (mm)

- Product Type

- PU Roller

- Color

- Yellow

- Width

- 260 Millimeter (mm)

- Length

- 910 Millimeter (mm)

Tin Printing Roller with PU Coating Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

About Tin Printing Roller with PU Coating

A tin printing roller is a specialized cylindrical component essential in the offset printing process used for decorating and applying coatings to tinplate (thin steel sheet coated with tin), which is primarily used to make food cans, lids, and other metal packaging.

Here is a detailed description:

Key Features and Function

-

Core Purpose: The roller's main function is to precisely transfer ink or coatings onto the non-absorbent, hard surface of tinplate.

-

Printing Method: It is a critical part of the offset printing unit, where it helps transfer the image from the printing plate (via a blanket roller) onto the metal sheet.

-

Precision and Consistency: Due to the high-speed and demanding nature of industrial metal packaging production, these rollers are manufactured with accurate dimensions and a fine surface finish to ensure uniform ink distribution and high-quality, consistent print output.

Construction and Material

-

Core: The roller typically has a sturdy metallic core, often made of steel or aluminum, providing stability and durability.

-

Surface Coating: The core is covered with a specialized external layer. For tin printing, these are often rubber rollers made from high-grade synthetic polymers like Nitrile (NBR), EPDM, or Silicone. The specific rubber compound is chosen for its:

-

Flexibility and Cushioning: To ensure even pressure and ink transfer across the rigid metal substrate.

-

Chemical Resistance: To withstand the specific properties of the high-performance inks and varnishes used in metal decoration.

-

Durability: To offer long-lasting usage under continuous operation.

-

Operational Environment

-

Hardness (Durometer): The roller's surface hardness is a critical specification, carefully controlled to optimize ink transfer and maintain print quality.

-

Temperature: They are designed to operate efficiently within a specified temperature range, often required to handle the heat involved in the printing and subsequent drying (or curing) processes.

In summary, the tin printing roller is a precision-engineered component designed to reliably and accurately apply graphics and protective layers to tinplate in the metal packaging industry.

Would you like to know more about the types of coatings applied to tinplate using these rollers?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PU Roller Category

Durable And Reliable PU Roller

Price 10000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Rigid

Usage : Industrial use, printing machine

Size : 1400

Material : Mild Steel / PU

Plywood Peeling PU Roller

Price 10000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Rigid

Usage : Industrial

Size : 200

Material : Mild Steel / PU

POLYURETHANE ROLLER

Price 500.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : Rigid

Usage : Printing machine, steel plant, conveyor system

Size : Various Sizes Available

Material : Mild Steel / PU

Polyurethane Roller

Price 8000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Hardness : 80

Usage : Printing Machine, Steel Plant, Indutrial Use

Size : 800

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free